News and information

A fantastic story that we want to share with you

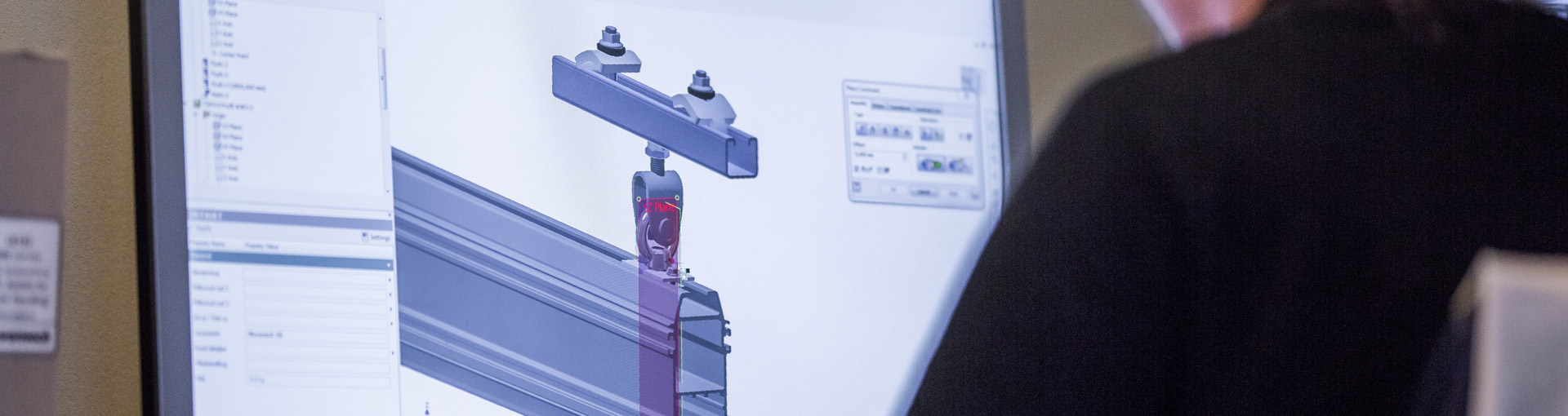

MOVOMECH LIFTING APPLICATION

Same liftingtool for 20 years and

1,400 000 tons later

In 2002, Movomech started a collaboration together with Tarkett in Ronneby and the rest is a fantastic story which we are happy to share with you.

Tarkett in Ronneby manufactures floors that are sandable and polishable and are excellent in environments where the floor is exposed to a lot of wear and tear.

There are around 30 Tarkett factories around the world, and at the plant in Ronneby they are over 550 employees.

In 2002, Tarkett contacted Movomech with a request that we should develop a solution that could move their floor rolls from stock pallet to order pallet. This resulted in a workingstation with four Mechlifts running in Movomech´s crane system MechrailTM.

In 2022, i.e. 20 years later, Tarkett turns to Movomech again and wants to order four next Mechlifts including a new crane system MechrailTM for the current workstations.

Here follows a short interview that was conducted just before the old lifters were to be replaced with the new ones.

Tarkett February 29, 2023

Give a short presentation about who you are and what you do at Tarkett

Pär Åkesson, works as a Supervisor. I have worked at Tarkett for 25 years and I started as a fork-lift operator and was given the opportunity to educate me to become a Supervisor via Tarkett.

Leif Persson, works as a consultant when it comes to projects. I come up with solutions on how Tarkett can renew their current equipment that has passed ”Best before date”. I do a preliminary study, present different scenarios such as, change a little or change a lot and gives justifications to why certain equipment needs to be replaced.

How did you get the idea to use Movomechs Mechlifts?

We did a preliminary study where we evaluated several options. Earlier, we pulled the carpet rolls with the help of our own body weight by using a spear-like mandrel.

With Movomechs Mechlift, we have now improved our ergonomics, safety and also that we have upgraded the handling weight. It is important to us that everyone should be able to work at Tarkett and be able to use our equipment in a smooth and simple way that does not strain the body.

What is the biggest advantage you see with this type of lifter from Movomech?

It is clearly the ergonomics, now we handle heavy weights unimpeded. Everyone from the shortest person to the tallest can handle the Mechlifts.

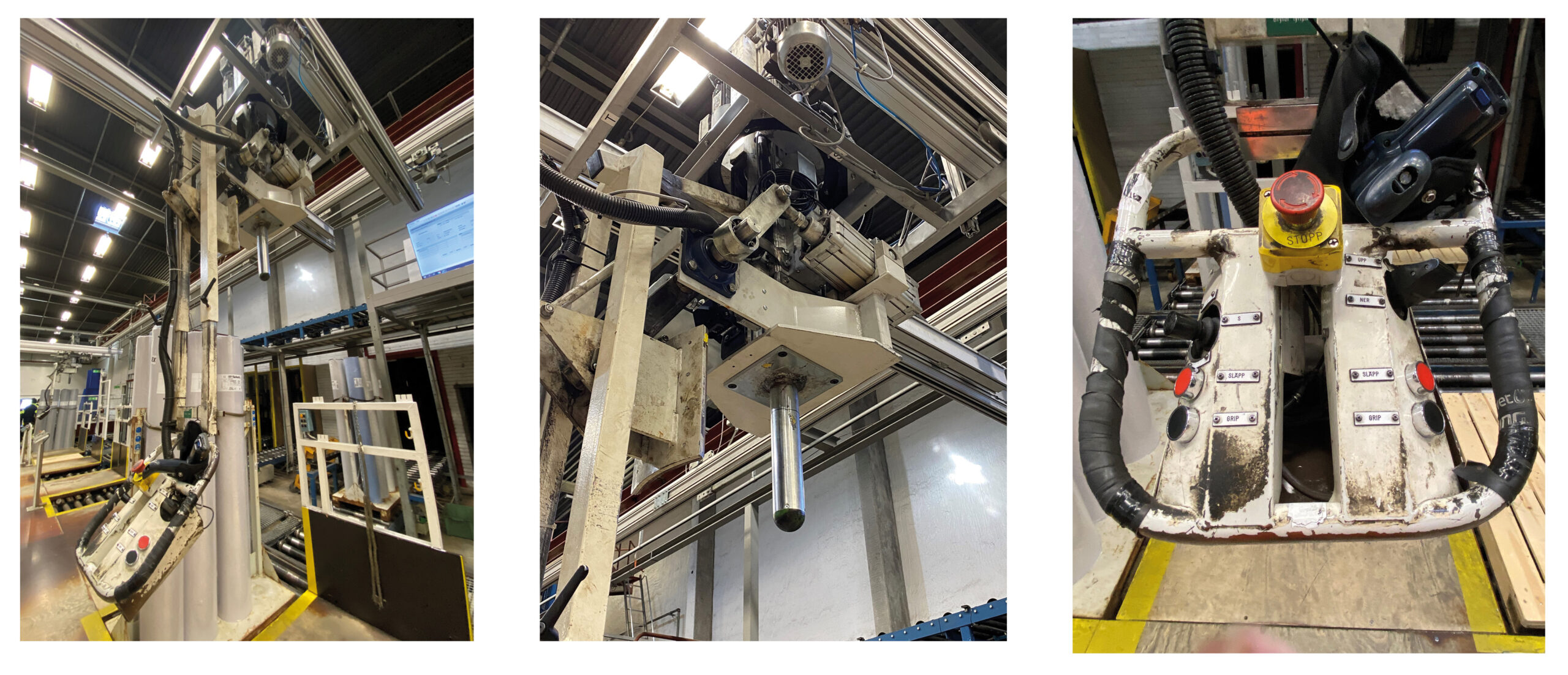

You have used your current Mechlifts for a full 20 years now.

Can you estimate how many tons they have lifted in total?

(This calculation is per lifting tool)

200 tons are lifted per day and per lifter.

350 days a year.

200 x 350 = 70,000 tons / year.

In 20 years this will be 1,400 000 tons / per Mechlift.

We can state that they fulfilled their work steps.

Have you had to do any extra manual work on them?

Regular maintenance only, we have replaced wear parts such as joysticks, buttons and trolleys from time to time, otherwise nothing.

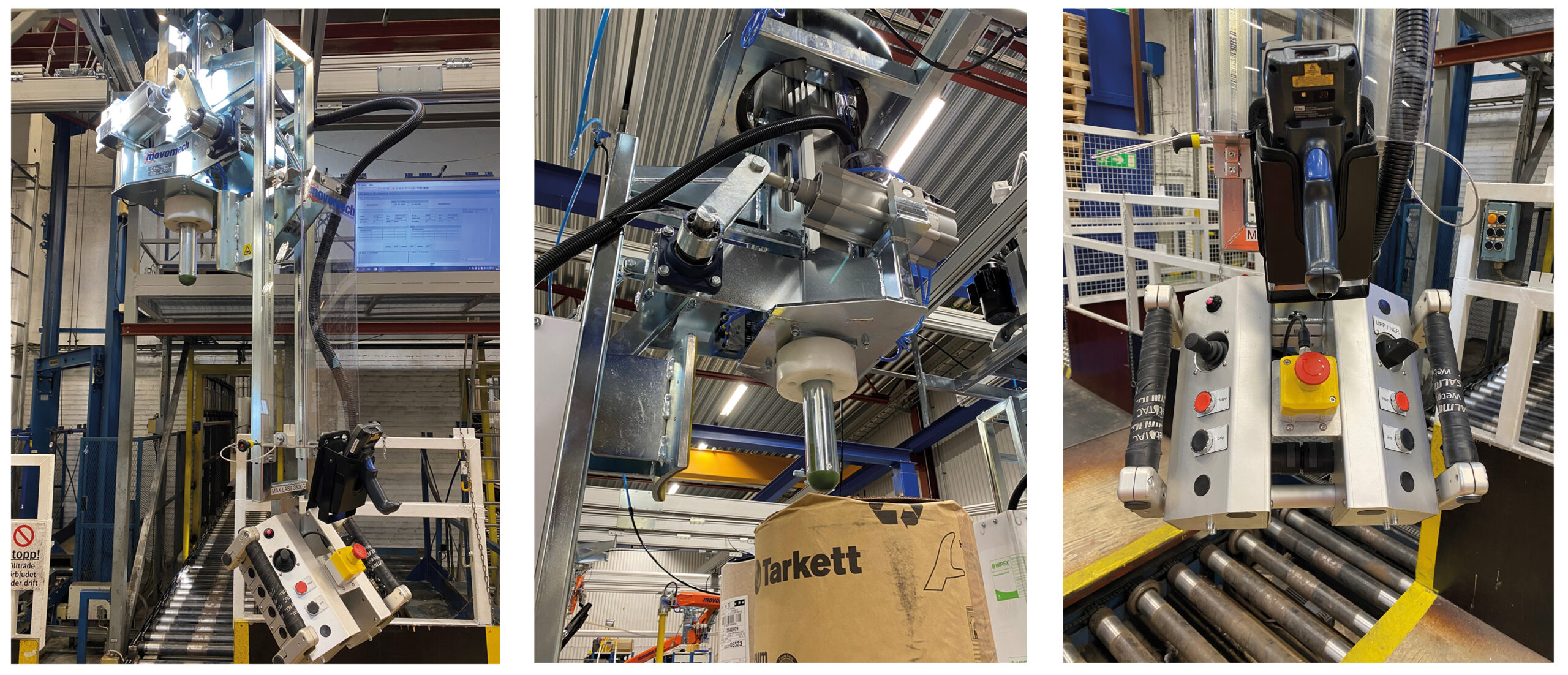

The week after this interview, Movomech installed their new lifters including new crane system.

Revisit on March 25, 2023

How did delivery and installation work?

Overall, it has worked smoothly.

The installation went impressively fast, from shutdown to start, everything was replaced in 48 hours.

We ran into a few issues when the new lifters were installed, but most of the problems have already been resolved.

How do the new Mechlifts work?

Very good!

The old ones did not have 360° rotation, the new ones is completely free-rotating. We saw on our old lifters that we needed to make reinforcements in certain areas on the lifters, these areas are now reinforced from the start so you can say that we together with Movomech developed the equipment.

Movomech wishes Tarkett all the best and good sales and growth.

Svenska

Svenska

Deutsch

Deutsch

Français

Français