News and information

Long-term test of new crane system profile gave double results

In October 2018, Movomech launched a new generation of aluminium profiles for the Mechrail™ light rail system, a profile series with updated design and new accessories. Long-term tests during the development period gave a slightly unexpected bonus result.

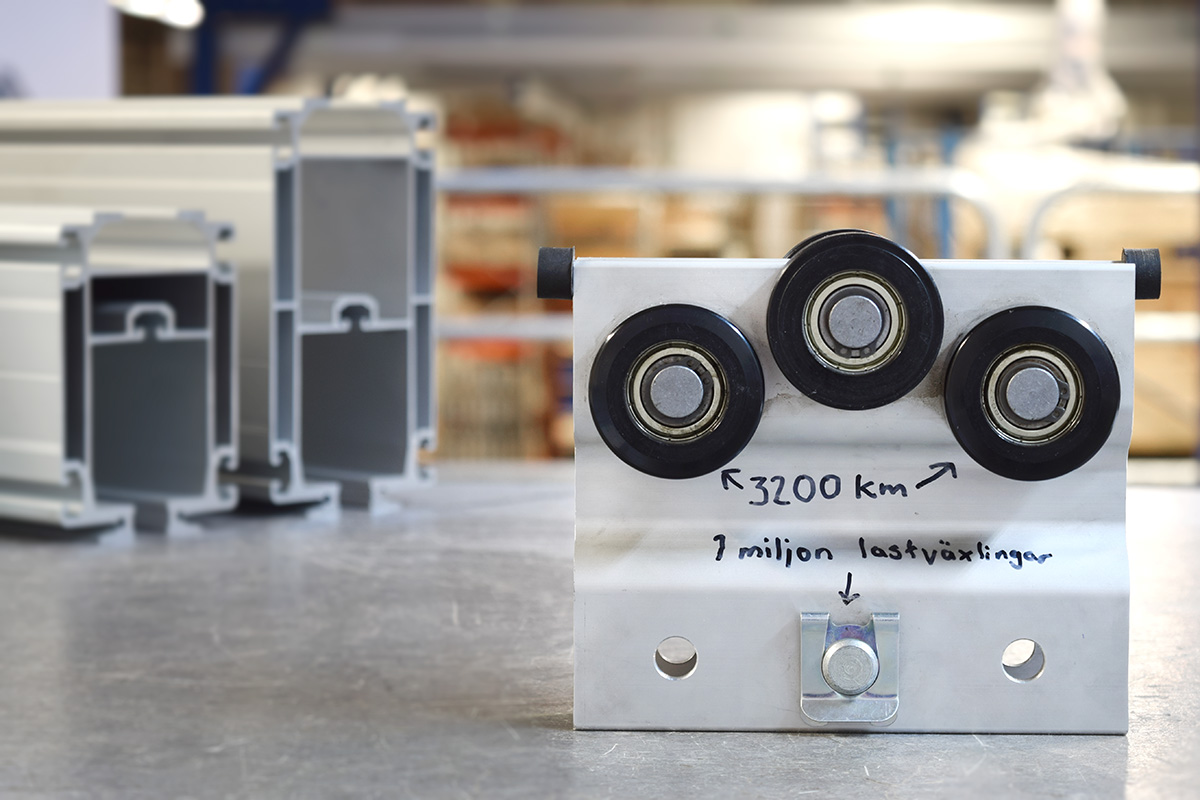

After long-term fatigue tests of the new profiles in the spring of 2018, a bonus outcome was discovered. Apart from the fact that the profiles and its new joint set design passed the strenuous fatigue tests without problems, it turned out that the classic trolley used in the test rig was still completely unaffected after over one million work cycles in continuous operation and with maximum load.

– I give great praise to my predecessors in the development department and the result confirms the trolley’s premium quality, says Emil Månsson, development manager at Movomech and responsible for the tests.

Emil Månsson, development manager at Movomech and responsible for the tests

– After evaluating the test results for crane system profiles and their accessories, this finding regarding the trolley became a bit of a bonus outcome of the tests. We thought maybe we would find at least some signs of wear or impact but no, nothing.

“We thought maybe we would find at least some signs of wear or impact but no, nothing.”

– The load-carrying trolley has had a largely unchanged design for decades, says Emil, and it is very unusual with problems caused by the trolleys. Even in tough material handling in multiple shifts. This test result confirms the feeling we have had, that our trolleys are incredibly durable, all the way from the chassis to the bearings and the rolling surface of the wheels.

How come the trolleys are so strong?

– The reason is probably our high quality requirements on the components, primarily the ball bearings and the plastic material in the wheels, determines Emil. They are fully optimized for their purpose. And that we have chosen to manufacture the trolley chassis in durable aluminium instead of in plastic has proved to be right in the long run.

Svenska

Svenska

Deutsch

Deutsch

Français

Français