News and information

Impressiv lifting performance

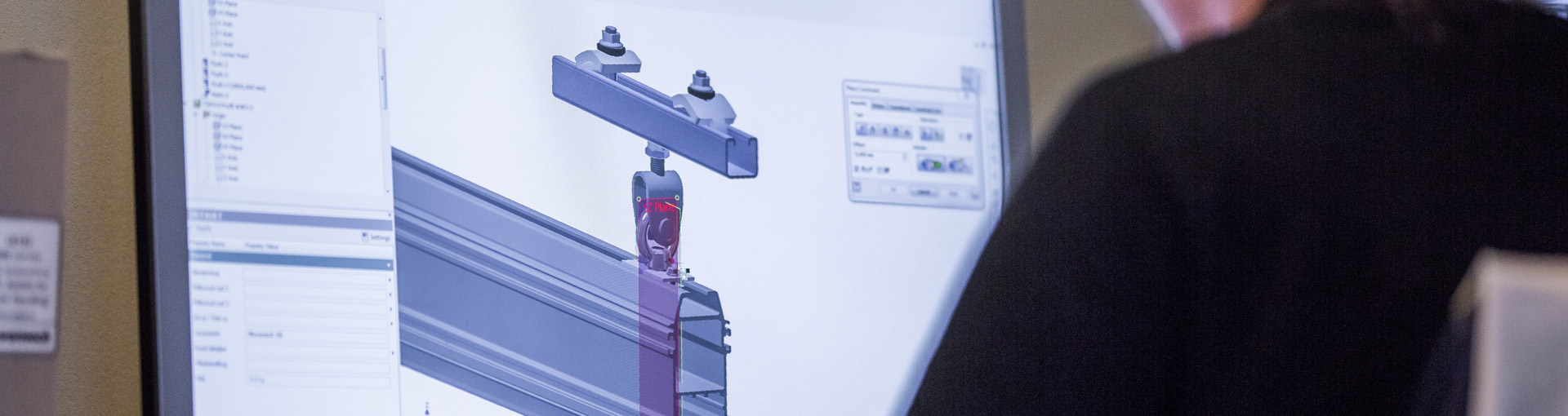

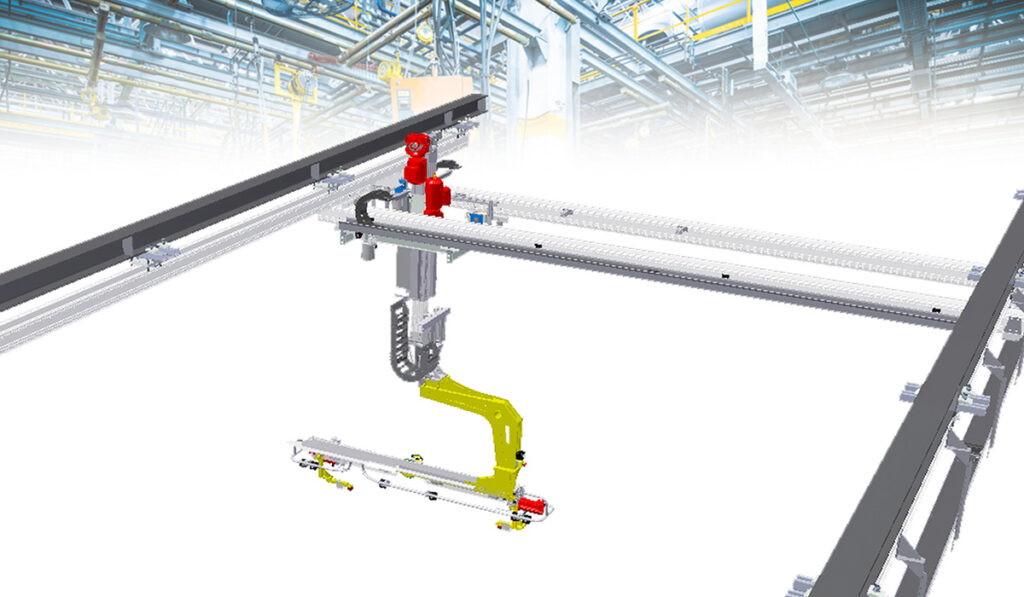

The cockpit manipulator was manufactured and installed in 2012 and had by early 2021 produced over two million vehicles.

How durable is a lifting equipment? With the right quality, service and maintenance, lifting manipulators can last far beyond normal warranty periods, even in the automotive industry’s tough production pace with high precision and availability requirements.

A while ago, Movomech International AB received good feedback from an impressed production manager at a customer in the automotive industry in northern Europe. The production line includes Movomech’s lifting manipulator Mechlift Pro, which has continuously delivered top results at a cockpit installation station (dashboard installation, ed. Note).

Key Account Stefan Hausdorf recounts customer feedback:

“They had looked back at the production figures from installation to now and totally underestimated its performance. The cockpit manipulator was installed in the summer of 2012, we made some minor modifications to the rotation units during the Christmas break in 2012, but otherwise no other changes have been made.”

So far, the manipulator had now manufactured an impressive 2,290,950 vehicles.

“What a performance! The best month was October 2014 when it built 31,318 vehicles.”

Stefan Hausdorf continues:

Since then, the lifting manipulator has finally retired this year, 2021.”

“We feel really proud when customers come back to us specifically because of our product quality. Not having to replace the equipment often is appreciated by our customers, and when it comes to fault-sensitive production, as within the automotive industry, durable and reliable equipment is valued particularly highly.”

Installation with lifting manipulator Mechlift Pro and pneumatic gripper tool for installation of dashboards

For more information about Movomech’s range of products and systems for lifting and material handling within Automotive, please contact Movomech International AB.

Svenska

Svenska

Deutsch

Deutsch

Français

Français